PCB Reliability Testing: Thermal Cycling, Vibration, and HALT/HASS Testing

Introduction

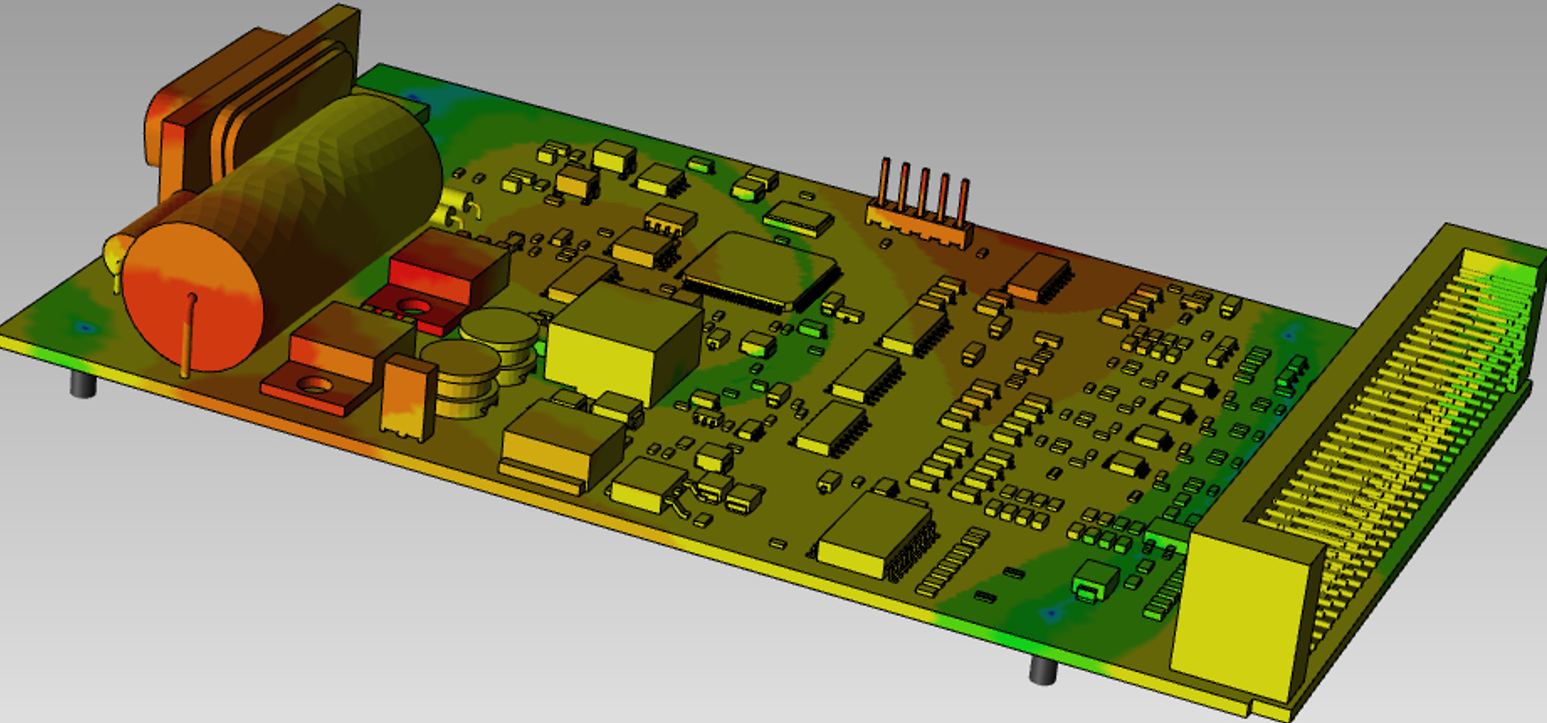

High-reliability and high-performance electronic equipment is more needed than ever today. The basic building block of such devices, printed circuit boards (PCBs), need to be very reliable to perform reliably in various operating and environmental conditions. PCB reliability testing is necessary for establishing a circuit board’s ability to withstand rugged conditions over the long term. The pcb layout service reliability testing is needed to determine the ability of a circuit board to endure in harsh environments in the long term. While FR4 has a tolerable heat resistance, it deteriorates at the same time as subjected to excessive-temperature publicity over a long length. This post covers each of these tests, their uses, and their significance in ensuring the longevity of PCBs.

A Deep Dive into Thermal Cycling, Vibration, and HALT/HASS Testing

The Significance of PCB Testing for Reliability

Throughout the life duration of the PCBs, they’re usually subjected to environmental and bodily stresses like mechanical vibration, ambient temperature, and ranging running situations. Fatigue and stress from those stresses should cause early failures like insulation failure, cracking of solder joints, or harm.

Prior to product marketing, PCB reliability testing simulates real conditions and identifies any flaws that may be present under controlled conditions. The assessments permit manufacturers to make certain that their PCBs will be characteristic as preferred all through their life, even in extreme conditions. Thermal cycling, vibration testing, and HALT/HASS testing are just a few of the most common methods; each is designed to counteract a specific stressor that can degrade PCB performance.

Testing for Thermal Cycling

One of the tougher tests of the integrity of PCB is thermal cycling. The thermal cycling test replicates the temperature effect of cycling temperatures to which a PCB will be exposed during the duration of its operational life. Within a specified time, the PCB is exposed to repeated cycles of extreme temperature fluctuations, generally low to high temperature or vice versa.

Because thermal cycling can cause mechanical stress as the materials expand and contract at different rates while they go through the temperature change, thermal cycling is of critical importance. This can ultimately result in element cracking, solder joint failure, and delamination of the PCB layers. Thermal cycling checking out determines the capability of the PCB to withstand such heat stresses without affecting its capability. Thermal cycling testing determines the capability of the PCB to withstand such heat stresses without affecting its functionality.

In automotive electronics, aviation, and industrial machine uses where electronics are exposed to high temperatures, this test method is extremely appropriate. This test can be utilised by manufacturers to test solder joints, components, and the reliability of the whole PCB design and see if they are able to survive extreme temperatures in the field without premature failure.

Testing for Vibration

Vibration testing is also a critical part of pcb design board reliability testing, particularly for products to be used in continuous motion or mechanical shock applications. Vibration replicates the stresses that a PCB would experience in consumer products, car, and aerospace programs.

The PCB is subjected to a range of frequencies and amplitudes in vibration testing, which is a simulation of the mechanical loads of actual service. It is tested to see if the PCB can withstand vibration and mechanical shock without delamination of layers, delamination of solder joints, or loose components.

In order to make a PCB structurally dynamically stable, vibration testing has to be performed. Engine running and driving conditions, for instance, subject PCBs to vibration across the automotive sector. In the aviation sector, where aircraft are subjected to continuous pressure fluctuation and mechanical motion, vibration testing ensures the PCB is where it is supposed to be and is working in flight.

HALT Testing

A stringent testing procedure known as Highly Accelerated Life Testing (HALT) is used to stress the PCB to its breaking point in a test environment. To find the breaking point of the PCB, HALT testing subjects it to extreme mechanical stress, extreme temperature shock, and extreme temperature cycling. It is performed with a view to finding the maximum tolerances of material and design prior to failure and to test the endurance of the PCB under normal operating conditions.

Subjecting the PCB to conditions much more stressful than conditions under which the PCB will be exposed when in use, HALT testing speeds up aging. By this method, the manufacturers can determine if there are any defects or design defects in the PCB in advance. By this method, the design can be improved by the designers before the mass production of the product, and thus it is optimum in the developing phase.

HALT testing is applied primarily in the field of high-reliability products where all components that must satisfy extremely high-performance requirements and failure cannot be allowed, such as in aircraft parts, military hardware, and medical devices. It is able to completely test the reliability margins, failure modes of the product, as well as its operating limits, which can enhance its overall design even more.

HASS Test

Similar to HALT, Highly Accelerated Stress Screening (HASS) aims to find early life failure in a production environment. In order to stress PCBs beyond operational conditions, HASS testing subjects them to severe environmental conditions (vibration, humidity, and temperature). HASS is conducted on finished products before they are shipped to the customer in contrast to HALT, which is conducted in the design stage.

HASS testing aims at the detection of manufacturing defects and validation of the operation of PCB as required under stress conditions. HASS testing enables manufacturers to identify defects that would result in field failure or premature returns of the products by subjecting the products to such stringent conditions early in the manufacturing process. Such a testing process can help maintain uniform quality and reliability during the manufacturing process.

In medical device, aerospace, and military equipment applications, where the reliability of product performance is most critical, HASS testing finds widespread application. It validates that all the PCBs are at the preferred level of quality and will remain in proper working condition under actual operating conditions.

Conclusion

A fundamental aspect of PCB design and manufacturing in the biggest semiconductor company is reliability testing. HALT/HASS testing, vibration testing, and thermal cycling are all critical processes employed by manufacturers and engineers to test and ensure the ruggedness of their PCBs in harsh environments. Apart from providing increased product reliability, the tests reduce the field failure rate, hence increasing consumer confidence and product brand. PCB reliability testing will grow and continue to play its part in future technology success as the demand for more sophisticated and reliable circuits continues to grow.